Got my SB v2 a few months ago, carbon frame, and bar.

Until now I was using a regular wrench or my bike multitool and it was OK, but after paying so much for this bike I want to buy a torque wrench in order to tight bearings, bolts, etc at the right torque and prevent over-tightening that can damage the carbon frame and components.

It looks like torque wrenches are pretty expensive these days. Saw this review and found it for S64.99 on Amazon. The 2-20 torque range fits my needs, and it is claimed to be accurate, well built, and easy to use.

Does anyone own/use this wrench?

road.cc

road.cc

Thanks!

Until now I was using a regular wrench or my bike multitool and it was OK, but after paying so much for this bike I want to buy a torque wrench in order to tight bearings, bolts, etc at the right torque and prevent over-tightening that can damage the carbon frame and components.

It looks like torque wrenches are pretty expensive these days. Saw this review and found it for S64.99 on Amazon. The 2-20 torque range fits my needs, and it is claimed to be accurate, well built, and easy to use.

Does anyone own/use this wrench?

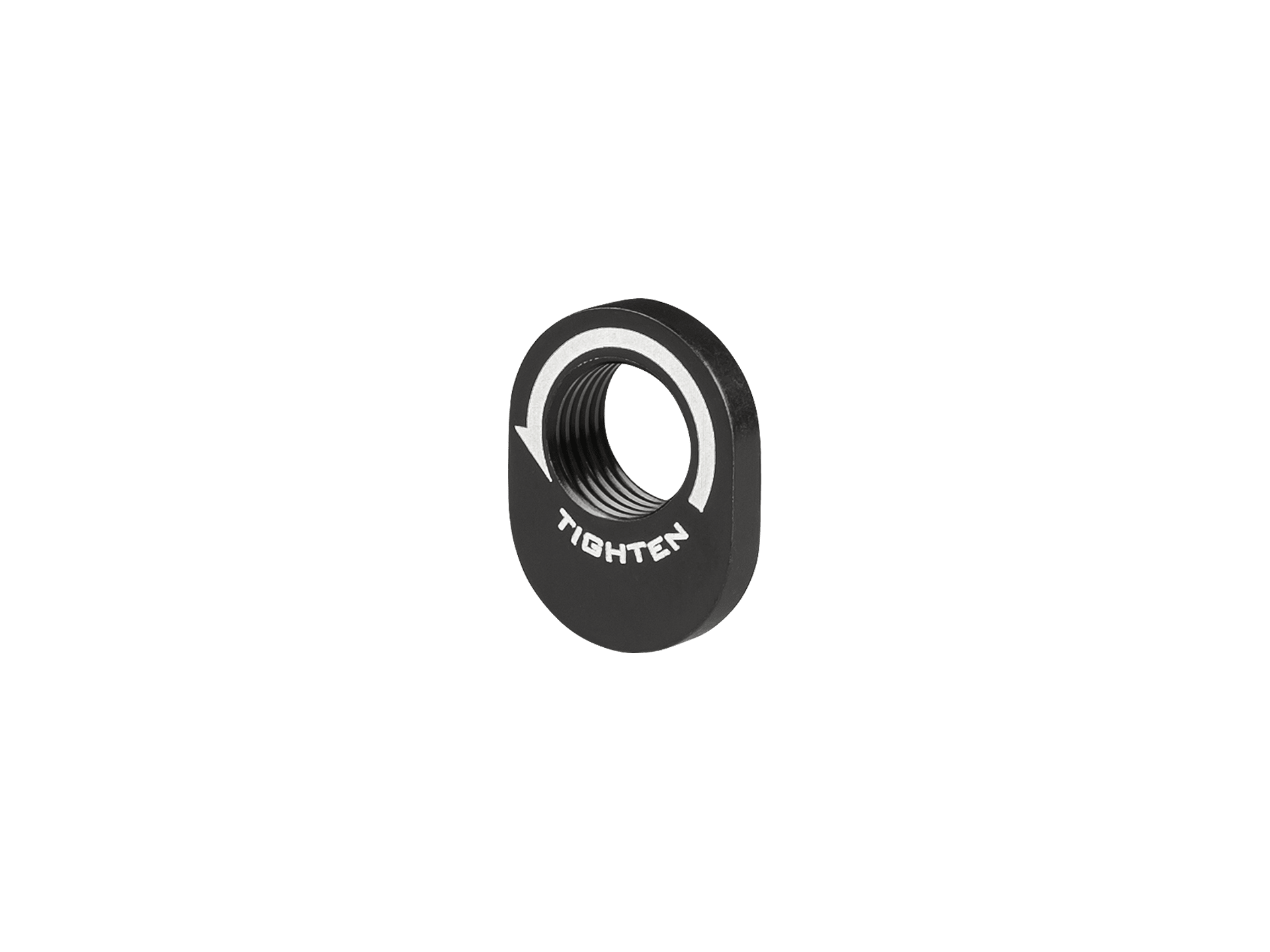

Pro Bike Tool 2-20Nm Torque Wrench set

Great price, well built, easy to use... there's a lot to love

Thanks!