Hey all,

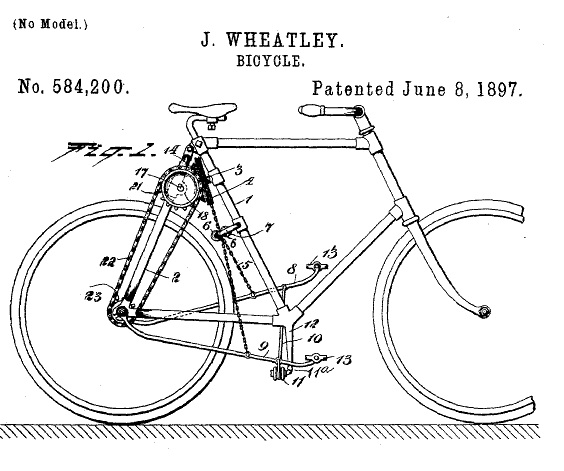

I'm working on a project involving a fully enclosed gear and chain system made specifically for fat bikes and the more extreme conditions and temperature they tend to be subjected to. It is similar to the known Pinion system but with a frame component encapsulating the chain as well and variations on the internal mechanism.

We're in the stage of trying to understand if there is any real interest for this type of solution. If you would like to have input into the project or voice any concerns, your answers to our questions below would be very much appreciated.

It is for the time being and academic activity but there is real design work that has been done to achieve what is likely a patentable product.

1) Do you have any problems with the current chain and derailleur system?

2) Would you see a benefit to an enclosed chain (built into the frame)?

3)What benefit would you see to a gearing system which allows for gear change at a stop or at full load?

Any feedback is appreciated.

Thanks,

Justin

I'm working on a project involving a fully enclosed gear and chain system made specifically for fat bikes and the more extreme conditions and temperature they tend to be subjected to. It is similar to the known Pinion system but with a frame component encapsulating the chain as well and variations on the internal mechanism.

We're in the stage of trying to understand if there is any real interest for this type of solution. If you would like to have input into the project or voice any concerns, your answers to our questions below would be very much appreciated.

It is for the time being and academic activity but there is real design work that has been done to achieve what is likely a patentable product.

1) Do you have any problems with the current chain and derailleur system?

2) Would you see a benefit to an enclosed chain (built into the frame)?

3)What benefit would you see to a gearing system which allows for gear change at a stop or at full load?

Any feedback is appreciated.

Thanks,

Justin