Has anyone experimented with different greases for Hydra rear hubs? I previously had a thing for loud hubs but now have a thing for quiet hubs lol. I can pack the hub with Dumonde free hub grease (not Pro X) and it will be next to silent for one ride then I'm back to noisy. Rather than run through all this Dumonde grease, I feel like a tackier grease in smaller quantities will last longer. What say ye? I may just start trying out a bunch of different greases and note how long they keep the hub quiet, for science of course.

Hydra grease?

1 - 20 of 27 Posts

Joined

·

957 Posts

Has anyone experimented with different greases for Hydra rear hubs? I previously had a thing for loud hubs but now have a thing for quiet hubs lol. I can pack the hub with Dumonde free hub grease (not Pro X) and it will be next to silent for one ride then I'm back to noisy. Rather than run through all this Dumonde grease, I feel like a tackier grease in smaller quantities will last longer. What say ye? I may just start trying out a bunch of different greases and note how long they keep the hub quiet, for science of course.

Be careful if you get too thick on the grease, you can get stuck pawls and end up damaging the hub. Maybe ask i9 what they recommend.

Joined

·

1,154 Posts

Yeah, listen to Cary. I would caution you against using anything heavier than NLGI0. I use Lubriplate 105 in all my hubs. Even though it's NLGI0, you should still apply it somewhat sparingly. Hubs always start off silent, but slowly grow louder over the space of the first few rides.

Joined

·

957 Posts

Ya that is something I’m concerned with. I’ll contact I9 and see what they recommend

Joined

·

628 Posts

Molykote TP42 paste (i believe is the same as DT Swiss special grease but lots cheaper) makes my DT Swiss ratchet super quiet, but does get louder after a few rides :S

Joined

·

1,719 Posts

I use Sram Butter in my DT Swiss ratchet, it keeps it pretty quiet.

Joined

·

957 Posts

I’ll try that out too, I have Slick Honey. How long does it last in the ratchet?I use Sram Butter in my DT Swiss ratchet, it keeps it pretty quiet.

Joined

·

408 Posts

I use phil tenacious oil. But I like em loud.

Joined

·

42,655 Posts

slick honey is **** for a freehub grease. it'll lubricate, but it's a really light grease. it breaks down fast and will make for a louder hub than what you're using now. I only use slick honey on interfaces that slide like suspension and dropper post stanchions.I’ll try that out too, I have Slick Honey. How long does it last in the ratchet?

I've used phil's tenacious oil in hubs before (Hope Pro II EVO) and it worked well. I'm using Dumonde Tech Pro 4x grease in my Hydra hubs now because that's what I9 recommends, and I like the texture of it a bit better. I9 is only going to recommend dumonde tech grease or oil depending on how much noise you want (grease for less, oil for more). they're not testing all of the lubricant options (there are nearly endless ones and they can't test them all). they're going to choose what they like and stick with it.

Joined

·

1,719 Posts

Last service was done back in July, maybe 250 miles ago and it's still pretty quiet.I’ll try that out too, I have Slick Honey. How long does it last in the ratchet?

Joined

·

403 Posts

As above - I9 just recommend the Dumonde stuff and say it makes the hub quiet, but my gut feel has always been that that the grease will always 'walk' away from the ratchet surface over time and the hub will end up being loud (backed up by experiences above).

I've got some of the Molykote TP42 to try in mine. It is waaayy thick and sticky out of the tub (imagine semi-frozen toothpaste), but mix a pea sized amount with a couple of drops (literally drops, as if you'd dunked a spoke into the bottle and then let it 'drip' off) of mineral oil (eg. Magura Royal Blood, Reverb oil, Shimano brake fluid, etc) and it thins out quite nicely to something close to Dumonde thickness.

If this latest grease concoction does the same as before and gets loud after a ride, I'll try some neat TP42 on the ratchet. In terms of gumming up the hub enough to make the pawls stick and the hub skip, I think it will have to be pretty sticky grease in the pawl seats.

The TP42 has a nice characteristic of being quite 'sticky' in tension but quite 'slippery' in shear - ideal for the DT ratchets, and perhaps this will translate to pawl type hubs too.

I've got some of the Molykote TP42 to try in mine. It is waaayy thick and sticky out of the tub (imagine semi-frozen toothpaste), but mix a pea sized amount with a couple of drops (literally drops, as if you'd dunked a spoke into the bottle and then let it 'drip' off) of mineral oil (eg. Magura Royal Blood, Reverb oil, Shimano brake fluid, etc) and it thins out quite nicely to something close to Dumonde thickness.

If this latest grease concoction does the same as before and gets loud after a ride, I'll try some neat TP42 on the ratchet. In terms of gumming up the hub enough to make the pawls stick and the hub skip, I think it will have to be pretty sticky grease in the pawl seats.

The TP42 has a nice characteristic of being quite 'sticky' in tension but quite 'slippery' in shear - ideal for the DT ratchets, and perhaps this will translate to pawl type hubs too.

I use Dumonde Tech Pro-X grease. I've found that if you inject it with a hobby syringe into the paw springs as well as on the ratchet surface, it keeps the hubs quiet for longer.As above - I9 just recommend the Dumonde stuff and say it makes the hub quiet, but my gut feel has always been that that the grease will always 'walk' away from the ratchet surface over time and the hub will end up being loud (backed up by experiences above).

Joined

·

957 Posts

I9 got back to me, he said "I suggest you use a combination of the dumonde tech freehub oil and a more liberal application of the pro x freehub grease to quiet that hub down. Using a tackier grease could risk an increase in drag on the hub." SO I ordered a small cup of Pro X. I have also heard Phil Wood Tenacious oil might work well? Or heavy gear oil used for vehicles? I have some 85-120 in the garage...

Joined

·

957 Posts

Well, I thought I’d try a small experiment tonight since I had to install a new XT cassette anyway. I took all the old Dumonde freehub grease out and put 3 drops of 85w-140 gear oil (automotive) in the hub and it actually made the hub nearly silent. Now, gear oil, similar to motor oil, gets thicker the hotter it gets (85 weight when cold, 140 weight when at operating temp). I can’t imagine a freehub gets hot enough to affect the gear oil to the point it reaches the 140wt so I’m not concerned about it at this point. Will give it a thorough test on Saturday and see how it does, I did some quick sprints in front of the house and had zero skipping. Worst case if I see more drag the further I get into the ride, I’ll know the temp in there is getting warmer and may step down to 80w-90 gear oil or lower. So far so GOOD!

It will be interesting to hear how this pans out. Where exactly did you put the 3 drops of oil? On the paws, on the ratchet, or a little bit of both?Well, I thought I’d try a small experiment tonight since I had to install a new XT cassette anyway. I took all the old Dumonde freehub grease out and put 3 drops of 85w-140 gear oil (automotive) in the hub and it actually made the hub nearly silent.

Also, just 3 drops of oil seems like a very small amount for the whole hub. When I've used the Pro-X grease, I inject a dab of grease behind every paw and smear a thin layer of grease on the ratchet. That's the equivalent of a lot more than 3 drops of oil.

Joined

·

403 Posts

Thanks for the heads up on the gear oil. Used to work well in King hubs too.

My Hydra is almost silent so far with the TP42 / mineral oil combo, but its not had a long ride yet...

My Hydra is almost silent so far with the TP42 / mineral oil combo, but its not had a long ride yet...

Joined

·

957 Posts

Just on the inside of the hub where the pawls ride. There was still some lingering Dumonde grease in there too. I didn’t pull every pawl out and clean it thoroughly before putting gear oil in. Not exactly science lolIt will be interesting to hear how this pans out. Where exactly did you put the 3 drops of oil? On the paws, on the ratchet, or a little bit of both?

Also, just 3 drops of oil seems like a very small amount for the whole hub. When I've used the Pro-X grease, I inject a dab of grease behind every paw and smear a thin layer of grease on the ratchet. That's the equivalent of a lot more than 3 drops of oil.

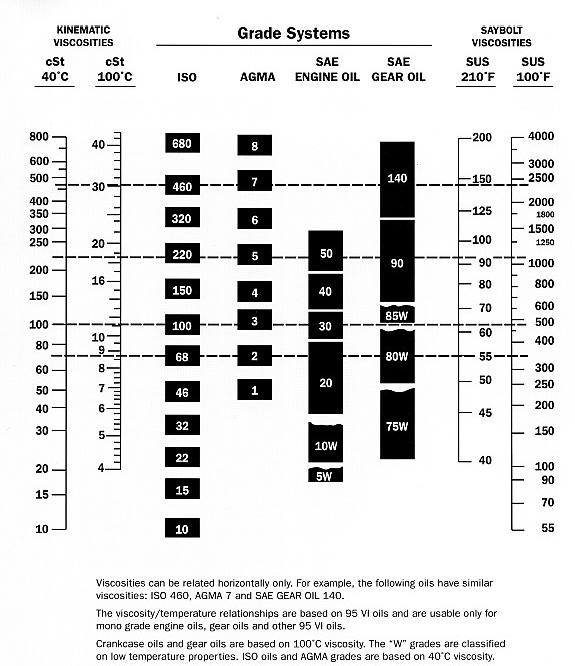

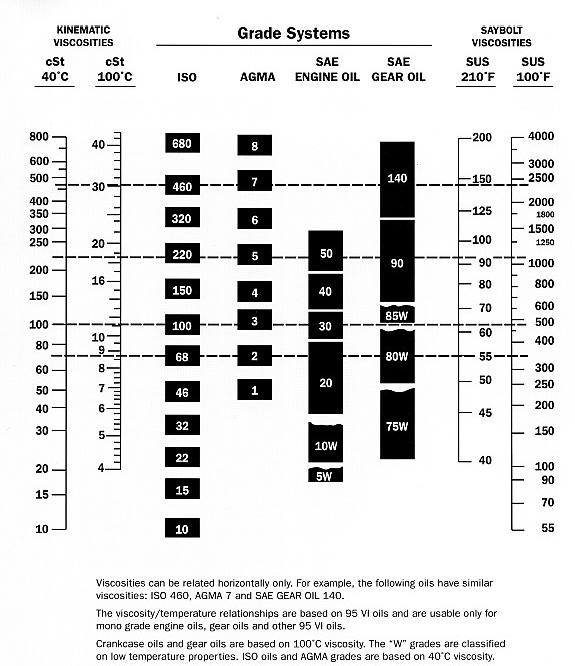

Your understanding is backwards. As oils get hotter, they thin. In what is termed a multiweight oil, the second number determines the thickness at operating temperature at 100c, the first number tells you the what cold weather pumping test an oil has passed. So for example, a 0w-40, 5w-40, 10w-40, 15w-40, and straight 40 weight oil will all have the same thickness at 100c of 12.5-16.3 cst. As the temperature decreases, the straight weight oil will thicken the fastest, the 0w-40 the slowest. The way that oils meet the cold temperature pumping test is a combination of the base oils used (synthetics are naturally multiweight to a degree) and pour point depressants.Well, I thought I’d try a small experiment tonight since I had to install a new XT cassette anyway. I took all the old Dumonde freehub grease out and put 3 drops of 85w-140 gear oil (automotive) in the hub and it actually made the hub nearly silent. Now, gear oil, similar to motor oil, gets thicker the hotter it gets (85 weight when cold, 140 weight when at operating temp). I can’t imagine a freehub gets hot enough to affect the gear oil to the point it reaches the 140wt so I’m not concerned about it at this point. Will give it a thorough test on Saturday and see how it does, I did some quick sprints in front of the house and had zero skipping. Worst case if I see more drag the further I get into the ride, I’ll know the temp in there is getting warmer and may step down to 80w-90 gear oil or lower. So far so GOOD!

Viscosity Charts - Bob is the Oil Guy

Viscosities can be related horizontally only Viscosities based on 96 VI single grade oils. ISO are specified at 40°C AGMA are specified at 40°C SAE 75w, 80w, 85, 5w, & 10w specified at low temperature. Equivalent viscosities for 100° & 210°F are shown SAE 90 to 250 and 20 to 50 specified at...

bobistheoilguy.com

For your use of rolling gear oils, I would suggest looking at CSt at 40c which is closer to the operating temperature you are working with. As the oil will get thicker as temperature decreases, this is when you will have issues with the pawls sticking or skipping. If you stick with gear oil, I would consider something like Redline 75w140, which is an ester based gear oil and will have among the lowest change in thickness as temperatures change (but still substantial).

Joined

·

13,183 Posts

I've had good luck with Pedro's synthetic grease in my hope hubs. Stay quiet quite a while.

Similar spring/pawl design. No idea if they are stronger or weaker than the springs in your hubs, but I've never had any issues.

Sent from my SM-G991U using Tapatalk

Similar spring/pawl design. No idea if they are stronger or weaker than the springs in your hubs, but I've never had any issues.

Sent from my SM-G991U using Tapatalk

Joined

·

957 Posts

Good info! This also leads back to me wondering if free hubs even get warm to the point where it would matter. I'm thinking no but riding during winter time may affect performance.Your understanding is backwards. As oils get hotter, they thin. In what is termed a multiweight oil, the second number determines the thickness at operating temperature at 100c, the first number tells you the what cold weather pumping test an oil has passed. So for example, a 0w-40, 5w-40, 10w-40, 15w-40, and straight 40 weight oil will all have the same thickness at 100c of 12.5-16.3 cst. As the temperature decreases, the straight weight oil will thicken the fastest, the 0w-40 the slowest. The way that oils meet the cold temperature pumping test is a combination of the base oils used (synthetics are naturally multiweight to a degree) and pour point depressants.

Viscosity Charts - Bob is the Oil Guy

Viscosities can be related horizontally only Viscosities based on 96 VI single grade oils. ISO are specified at 40°C AGMA are specified at 40°C SAE 75w, 80w, 85, 5w, & 10w specified at low temperature. Equivalent viscosities for 100° & 210°F are shown SAE 90 to 250 and 20 to 50 specified at...bobistheoilguy.com

For your use of rolling gear oils, I would suggest looking at CSt at 40c which is closer to the operating temperature you are working with. As the oil will get thicker as temperature decreases, this is when you will have issues with the pawls sticking or skipping. If you stick with gear oil, I would consider something like Redline 75w140, which is an ester based gear oil and will have among the lowest change in thickness as temperatures change (but still substantial).

1 - 20 of 27 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 16M

- members

- 534K

- Since

- 1990

A forum community dedicated to Mountain Bike owners and enthusiasts. Come join the discussion about bike parts, components, deals, performance, modifications, classifieds, trails, troubleshooting, maintenance, and more!

Explore Our Forums

Top Contributors this Month

View All

ForaFrank

386 Replies

3_Dimensional

344 Replies

Jayem

328 Replies